Typical Calibration Procedure of Differential Pressure Transmitter

Calibration Procedure of Differential Pressure Transmitter

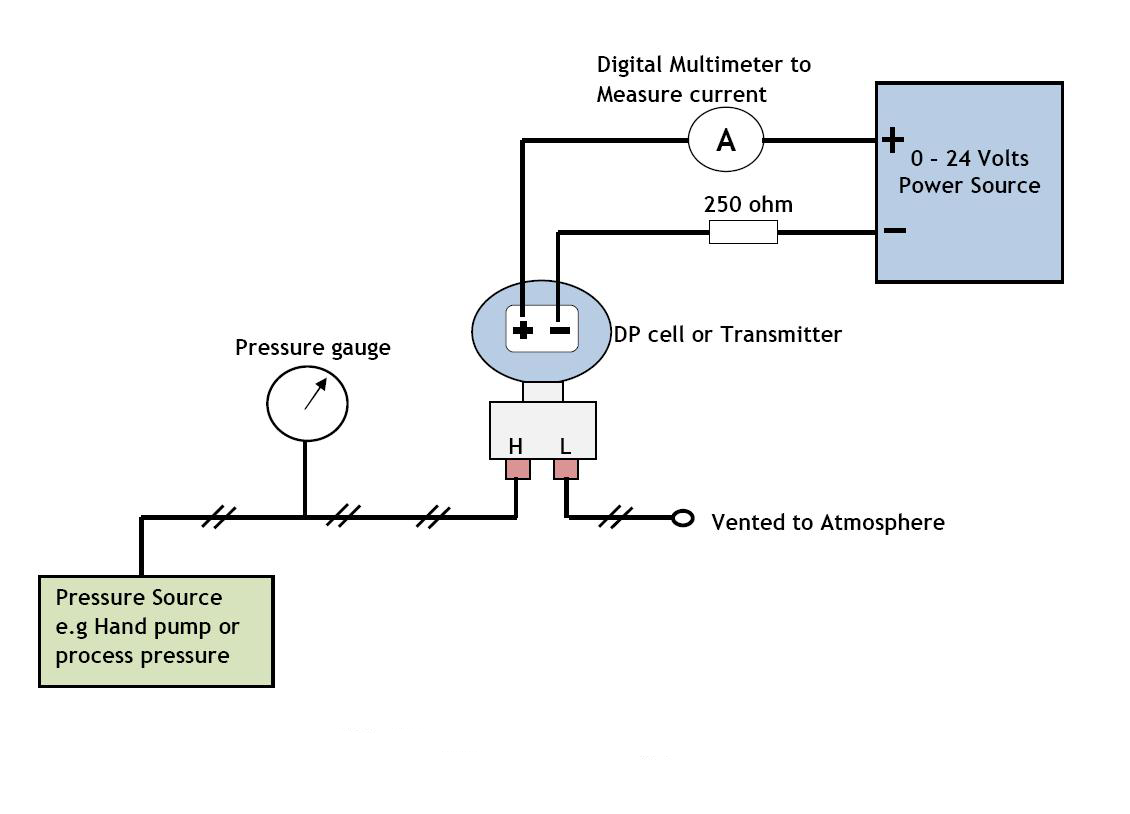

- Set up the differential pressure transmitter, HART communicator, power supply, hand pump, and the multimeter as below (see below calibration setup file).

- Make sure the equalizing valve manifold is closed.

- Apply a pressure to the transmitter equal to a lower range pressure (usually it correspond to 4 mA in the transmitter output). For example we have 0 to 100 mBar calibrated range, then the lower range pressure is 0, or let’s say we have -2 psig to 5 psig then we have lower range pressure equal to -2 psig.

- Read the pressure in the transmitter LCD (or in the HART communicator). Adjust (if any) through the HART communicator so that the output of the transmitter (on LCD) is the same with the applied pressure.

- Read the mA output of the transmitter by using a multimeter. Adjust (if any) through the HART communicator so that the output of the transmitter (on multimeter) is 4 mA.

- Apply a pressure to the transmitter equal to an upper range pressure (usually it correspond to 20 mA in the transmitter output).

- Read the pressure in the transmitter LCD (or in the HART communicator). Adjust (if any) through the HART communicator so that the output of the transmitter (on LCD) is the same with the applied pressure.

- Read the mA output of the transmitter by using a multimeter. Adjust (if any) through the HART communicator so that the output of the transmitter (on multimeter) is 20 mA.

Typical tools required:

- 24 VDC power supply

- Multimeter digital

- Pneumatic hand pump (up to 600 psig)

- Hydraulic hand pump (up to 10.000 psig)

- Low pressure hand pump

- High precision digital test gauge

- HART communicator

- Screwdriver toolkit

Note: point number 1, 2, 7, and 6 of the typical tools above can be replaced by a single multitester available in the market.

Comments

Post a Comment