Programmable Automation Controller (PAC)

Programmable Automation Controller (PAC)

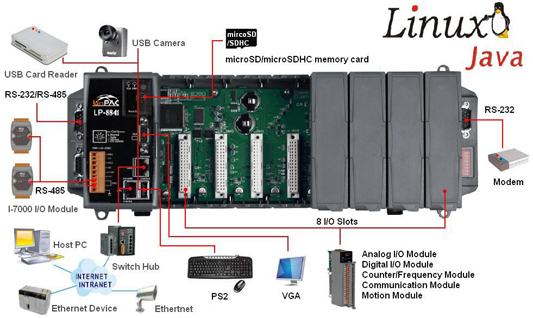

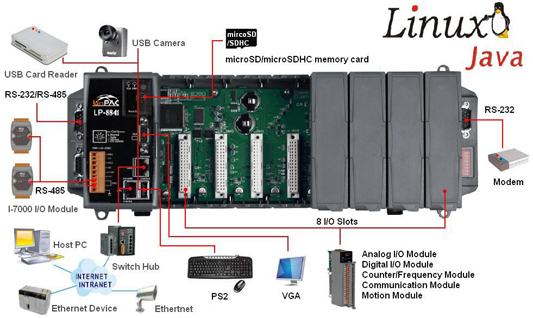

Programmable Automation Controller or PAC is an easy to configure PLC style device. It has advanced capabilities and they are already built into its design. It can perform complex functions like loop control, latching, and data acquisition and delivery. They have other advantages too as open architectures are used in their manufacturing and they can connect to almost any device or business system present today.

Characteristics of a PAC

The term PAC was given by ARC and there were two reasons behind it.

Operate using a single platform: It should be true for single or multiple domains and in drives, motions and process controls.

Employ a single development platform: It should use single database for different tasks in all the disciplines.

Functional Benefits

The characteristics used to define a PAC also explain the benefits that can be obtained from its industrial installation and application. A PAC can meet complex requirements and does not need additional components like a PLC. Due to high integration of hardware and software, improved control system performance is experienced. Integrated Development Environment or IDE which is used in the manufacturing of a PAC uses a tagname database that is used and shared by all the development tools.

A PAC only needs one software package to cover all the existing automation needs and the ones that may arise in the future and does not need utilities from different vendors. The control systems can be upgraded easily and due its compact size, a programmable automation controller uses lesser space compared to other options.

Programmable Automation Controller or PAC is an easy to configure PLC style device. It has advanced capabilities and they are already built into its design. It can perform complex functions like loop control, latching, and data acquisition and delivery. They have other advantages too as open architectures are used in their manufacturing and they can connect to almost any device or business system present today.

Characteristics of a PAC

The term PAC was given by ARC and there were two reasons behind it.

- To help the users of automated hardware define the applications they need.

- Give the vendors a term to effectively communicate the characteristics and abilities of their product.

Operate using a single platform: It should be true for single or multiple domains and in drives, motions and process controls.

Employ a single development platform: It should use single database for different tasks in all the disciplines.

Functional Benefits

The characteristics used to define a PAC also explain the benefits that can be obtained from its industrial installation and application. A PAC can meet complex requirements and does not need additional components like a PLC. Due to high integration of hardware and software, improved control system performance is experienced. Integrated Development Environment or IDE which is used in the manufacturing of a PAC uses a tagname database that is used and shared by all the development tools.

A PAC only needs one software package to cover all the existing automation needs and the ones that may arise in the future and does not need utilities from different vendors. The control systems can be upgraded easily and due its compact size, a programmable automation controller uses lesser space compared to other options.

Comments

Post a Comment